control parameters vertical raw mill

Haas Parameter List Helman CNC

Haas parameter list (mill/lathe) for cnc machinists who work on Haas cnc lathe/mill. Parameters are seldommodified values that change the operation of the machine. These include servo motor types, gear ratios, speeds, stored stroke limits, ballscrew compensations, motor control .

Square Bar Rolling Mill

Square Bar Rolling Mill. Raw material: Round steel wire Final Products: Fat wire . Technical Parameters. motor is 22KW. It also depends on the products. max round bar of raw material is 12mm. are 4 sets of rolling mill together, three of them are horizontal rolling mills and another is vertical rolling mill. speed is ...

Mill Noise Level Report Ref A FvdM GIBB

Cement Mill Noise Level and Attenuation Report Page 2 1. Executive Summary The study was conducted to establish if the noise radiated by two different cement grinding technologies, a conventional ball mill and a vertical (roller) mill, would be sufficiently attenuated at the boundaries of the proposed sites to adhere to regulations.

The Hot Rolling Process California Steel Industries

The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next process.

Modelling of the vertical raw cement mill grinding process ...

And it's to use a cement plant raw cement vertical mill grinding process parameters to training and testing data of the model. After comparing with the BP neural network model, the experimental results show that the proposed modeling method is effective, and the raw cement vertical mill grinding process operation process stability has increased.

Formation and Techniques for Control of Sulfur Dioxide .

by inline raw mills, process alterations, dry reagent injection, hot meal injection, spray dryer absorber, and wet SO2 scrubber. REFERENCE Miller, F. M., Young, G. L., and von Seebach, M., Formation and Techniques for Control of Sulfur Dioxide and Other Sulfur Compounds in Portland Cement Kiln Systems, RD Serial

Arabian Cement Company Jeddah Saudi Arabia : Engineer ...

Nov 27, 2013· Operating Ball mills, VRM (vertical raw mill), kiln operating of dry process. Precalcinary kiln in an optimum and efficiency from With computerized process control. for steady operation of kilns, production of good quality clinker with optimum fuel .

Upgradable intelligent solutions for process optimisation

Mills (raw meal mill, clinker mill, coal mill) Flue Gas Cleaning . Artificial Intelligence Real Benefits 3 ... Result through Powitec Control: Reduced NH4OHconsumption at reduced NH3slip . Artificial Intelligence Real Benefits ... Suitable for vertical mills (ball and roller) and horizontal ball mills Indication of mill filling degree.

all parameters for vertical raw mill

control parameters vertical raw mill, control parameters vertical raw mill;, for raw material grinding øC A B Roller mills from Polysius efficiently grind all raw materials for the clinker manufacFree Quote. control parameters vertical raw mill .

Cutting Parameters Optimization in Milling Of P 20 Tool ...

Cutting Parameters Optimization In Milling Of P – 20 Tool Steel And En31b 41 | Page A recessed portion of the tool's crosssection that conveys chips away from a .

loesche raw material grinding mill lm

LOESCHE to supply two vertical roller mills to Tanga ... The order covers the full engineering and supply of two LOESCHE vertical roller LM which will grind cement raw material at a product rate of 200 tons per hour with a fineness of 15 percent R 90 μm and one LM D coal mill with a grinding capacity of 20 tons per hour with a fineness of 12 percent R 90 μm.

CERAMIC MATERIALS I

Dr. Ayşe KALEMTAŞ COMMINUTION Comminution entails reducing the particle size of the raw material by crushing, grinding, and milling or fine grinding. In mineral processing parlance, comminution in coarse range is known as "crushing" and in fine range it is called "grinding". Comminution : The act or process of reduction of particle size with

vibration vertical roller mill Page 1 of 2

Mar 01, 2016· re vibration vertical roller mill. There are a number of reasons for high vibrations in vertical roller mills, such as: 1. Failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concrete.

Personal CNC Mill | Mini CNC Machine | Hobby CNC Mills ...

Personal CNC Mill from SYIL. The best mini CNC machines at an affordable price. Great hobby CNC mills. Made in China with global delivery. Get your quote now!

Time saving tips for Mazaks: Machining in the ZONE

Now assign each of those standard tools a standard name. On a Mazak mill, these would be called something like "EMILL .25A" – write that name on the list. Print that list out and give it to all the programmers, setup people and machinists working on these CNCs.

MIYANO TSV21 25 CNC VERT MILL FANUC PC PARAMETER .

we do not ship on customer's ups or other carrier accounts. arpi accounts used only. we offer a 120 day warranty on all parts. best warranty on ecrater, only if purchased thru ecrater!!! this part came from a miyano tsv21 cnc vertical mill with fanuc om control that we dismantled.

CSMVD Series Air Classifier Mill ALPA Powder Technology

The material is evenly fed into the grinding chamber by the feeding system, strongly impacted by the highspeed rotating grinding disc. At the same time, it is subjected to centrifugal force and collides with the grinding ring gear, and is subjected to various comprehensive forces such as shearing, friction and collision to finished grinding.

Take the Plunge: Drill vs. Mill : MoldMaking Technology

Aug 01, 2016· Take the Plunge: Drill vs. Mill. ... Rough milling operations can take hours on large components and typically remove more than half the raw material by volume. Selecting the proper machining method for the component and machine tool creates a successful and stable system. ... The initial cutting parameters of the highfeed mill, when taking a ...

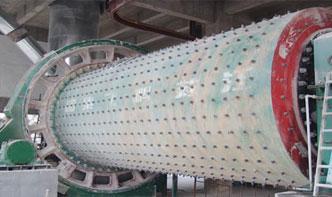

Raw Material Vertical Roller Mill

Raw Material Vertical Roller Mill is a type of industrial equipment used to crush or grind materials into small particles. Our raw materials vertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum.

Process Fans Used in Cement Industry SlideShare

Feb 23, 2016· Raw mill fans: Raw mill fan in cement industry carries gas and raw meal. The pressure drop in raw mill fan is very high. If a vertical roller mill is used for raw grinding in cement industry then a large raw mill fan is installed. Usually cement industries use centrifugal fans to carry out this process. 4.

Adding a full 4th axis to a HAAS vertical mill.

Dec 10, 2014· Adding full 4th Axis to a Haas Vertical Mill means that the rotary product is plugged in directly to the machine and machine controls all rotary functions. Complete with interface, motor, etc is very confusing because interface means you have a seperate controller box for the rotary (this is NOT full 4th Axis) motor, etc is very vague. The ...

Hydrocyclone Feed Pump Pressure PSI vs Operating Parameters

Hydrocyclone Feed Pump Pressure PSI vs Operating Parameters ... your equipment has variable control on the apex size it is very important that it remain within the correct operating parameters. By changing this one control it can become impossible to maintain pressure and density at .

Latest Posts

- سنگ بالاست از جنوب امریکا

- سجل النقالة والفروع طاحونة

- الكرة مطحنة كفاءة العوامل

- سوق الاجهزة الرياضيه في ليبيا

- 2400 x 8000 حجر

- المعدات المستخدمة في محاجر الحجر البازلتي

- آلت ثني حديد البناء

- سحق النبات مصنعين في الصين

- مصنع الصابورة سحق في كينيا

- مسحوق الطين البنتونيت

- مطحنة الأسمنت بدف كسارة هرغا

- الفضة طحن النبات

- حقيبة تغذية الذرة في جنوب أفريقيا

- كتلة ملموسة صنع أوك الحجر كسارة آلة

- بيليه الصحافةالأسطوانة أمبير يموت بيليه مطحنة آلات

- big crusher mobile portable crushing crusher

- mini dairy plant in the philippines

- equipments and construction machinery pdf

- esquema mineria cielo abierto

- jackson grinding mill 2a

- aggregate crushing lines in uae

- artificial sand making plant for sale

- schneeberger grinder auctions

- silica sand removing impurities

- prices of mining equipment

- iron ore cone crusher suppliers pakistan

- rinci pict jaw crusher dan motor

- floating wash plant yukon gold

- diagram of roller mill for partice size redution

- supplier of grinding rod for ball mill in south africa