raw mill ball

Closed circuit systems for ball mills | Industrial ...

Reductions in the range of 46 kwh/t cement are reported from India, depending upon the product type. In China, for 5000t/d cement production line using a ball mill with closed circuit system, power consumption index is reported to range between 38 ~ 42kWh/t (NDRC, 2008. ).

Grinding Aids for Ball Mills | Industrial Efficiency ...

A ball mill generally loses its grinding efficiency remarkably at fine grinding. This is because fine particles from ground materials agglomerate and adhere to the mill liners or grinding media as coating, reducing the impulsive force of the mill. In addition, the agglomerated particles are mixed into the coarse powder in the separator and recirculated through the mill.

Ball Mill Ventilation | VDChari

Jul 10, 2018· Ball Mill Ventilation The main objectives of mill ventilation are to ensure the cooling of the mill, internals and for dedusting. If temperature of the mill goes above 110oC due to less ventilation. Dehydration of the gypsum takes place and creates quality problems like false set and low fluidity of cement. It causes coating in [.]

Polysius Roller Mills. For grinding

8 Polysius roller mills.....for raw material grinding. øC A B Roller mills from Polysius efficiently grind all raw materials for the clinker manufacturing process – ranging from soft to very hard, from dry and fine to very moist and sticky and from slightly abrasive to extremely abrasive. This grinding system includes a feed belt conveyor ...

raw material vertical mill wet ball mill slag

Jun 20, 2018· raw material vertical mill wet ball mill slag Vertical Mill LUOYANG ZHONGTAI INDUSTRIES CO.,LTD. LGMS series vertical mill slag cement and cement raw materials LGM series vertical mill is a comprehensive large scale grinding equipment, set of crushing, grinding, classifying, drying, material handling five functions into one, with a focus on process,

Ball Mill Production Line

Ball Mill Production Line The ball mill is widely used in the fields of building materials, mineral processing, chemical industry, electricity, etc, it can grind ores or .

raw material grinding ball mill

Ball Mill. For grinding raw material and coal the airswept ball mills are one proven grinding system. These mills are used to grind moist material that need to be. Chat Online. Grinding Mill Design Ball Mill Manufacturer 911 Metallurgist. Jan 11, 2018 . Rod mills are used for primary grinding of materials with a top size of .. of the ...

raw gold grinding ball mill

Professional cement raw ball mill cement raw grinding mill machine for sale .. Small scale gold mining ball mill 900*3000/China ball mill prices/Cement mill. Chat Online. 1200mm Gold Grinding Wet Pan Mill/two Roller Wet Pan . As an excellent equipment to work replacing the ball mill, the gold grinding wet pan . B. The gold grinding wet pan mill ...

Cement Raw Mill Ball Mill Grinding Wholesale, Ball Mill ...

offers 480 cement raw mill ball mill grinding products. About 50% of these are mine mill, 1% are grinding equipment. A wide variety of cement raw mill ball mill grinding options are available to you, such as free samples.

Ball Mill,Ball Mill Supplier,Ball Mill For Sale,Ball Mill ...

Shanghai Clirik is a Leading Minery Manufacturing Company in all Types Of Ball mill,Cement Ball Mill,Ball Grinding Mill and so to our company for .

VRM vs Ball Mill for Cement Grinding Page 1 of 1

Feb 10, 2016· gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution and how does it compare with the product of a ball mill relative to these parameters. Other parameters(VRM vs. Ball Mill) to be considered are the following:

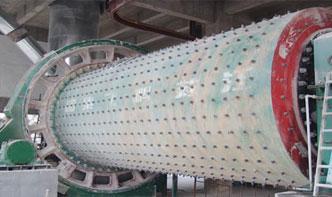

I Ball mill maintenance Fathom Engineering

A ball mill is a large cylindrical tube partially filled with steel balls. The ends of the steel cylinder are attached to trunnions that are supported on journal bearings. As the ball mill rotates, the steel balls in the cylinder rise up on the mill's inside surface and eventually tumble down to the bottom. The raw material is fed into the ball ...

Ball mill is mainly used to grind raw materials in some ...

Apr 01, 2014· Ball mill is mainly used to grind raw materials in mining, cement, refractory material, chemical can be divided into dry and wet wet ball mill works,the materials are put with a certain amount of water or other liquid in order to .

XBMTube Ball MillBall Tube MillCement MillRaw Grinding ...

Raw mill used for cement raw materials grinding, applied to various types of cement clinker. Tube mill main components are: cylinder, feeding and discharging part, transmission part, etc. Tube mill is widely used in building material, metallurgy, mineral processing, electricity and chemical industry for cement and other materials grinding.

HOW BALL MILL WORKS?

Oct 10, 2016· The ball mill is a hollow drum closed with loading and unloading end caps, filled with grinding media and rotated around its drum of the ball mill (Pic. 1) is a hollow cylinder of steel, lined inside with armor lining plates which protect it from impact and friction effects of the balls and the grinding material.

Gold | Copper Mine Ball Mill Lining Aim Precision ...

A ball mill is a type of grinding mill, which purpose is similar to the sag mill or other mining crushers. These machines are used to grind or mix metals or raw materials for further processing. Various materials are placed into the mill drum and rotated with the mined materials that are to be crushed.

Latest Posts

- القوة المركزية في الغسالة

- محطم الأنتيمون stibnite

- طاحونة للدراجات الطائرات الطائرات الدوارات الفرامل

- كسارات بنات يوتوب

- صورة لرجل يعمل طاحونة في كينيا

- الأعمال الميكانيكية الكاولين الرمال

- طحن باللس للمطحنة الخام

- قطعة ل سم كسارة

- الفك محطم لوحات للبيع

- حيث لشراء فروع كسارة في كينيا

- الكروم التعدين المعدات السعر في جنوب أفريقيا 2000 تيساب أرك

- يبحث من اقتناء مطحنة الأسمنت

- مشروع طاحونة كربونات كالسيوم

- من خام الذهب

- cwp dense media coal washing for sale

- mixing ratio of concrete with crushed volcanic rock as aggregates

- chemical mining methods for gold ehow

- soil bricks making machine in pakistan

- ball mining and metallurgy equipment co

- reviews of grinding mill model for metallic scarps ing bonfiglioli

- vertical mill producer zenith in china

- stone crasher machine manufactures in china

- silver ore refining plants and machinery

- ccg 1700 concrete granite polishing machine html

- thin iron mill price

- list of coated abrasive plants in germany

- for industrial equipments

- difference between horizontal and vertical milling machine ppt

- high hammer crusher ore india

- calculate crusher