the gypsum reduction process for sulphur

Reductive Decomposition of Gypsum by Carbon Monoxide

Reductive Decomposition of Gypsum by Carbon Monoxide Sulfur dioxide and lime can be produced from gypsum under newly determined conditions. Process provides a new route for manufacturing sulfuric acid from gypsum TREMExDOcS domestic reserves of gyp sum and anhydrite constitute a potential source of raw material fix sulfurbased chemicals.

WebElements Periodic Table » Sulfur » the essentials

Sulfur: isolation. Isolation: it is not normally necessary to make sulphur in the laboratory as it is so readily is found as the native element in nature and extracted by the Frasch process. This is an interesting process since it means that sulphur can be extracted from underground without mining it.

Recovery of Sulphur from Waste Gypsum CiteSeerX ...

Recovery of sulphur and calcium carbonate from waste gypsum Oct 5, 2007 Recovery of sulphur and calcium carbonate from waste gypsum. NR Nengovhela1*, CA Strydom2, JP .

Sulfur Oxides: Pollution Prevention and Control IFC

Sulfur Oxides: Pollution Prevention and Control 259 Emissions Control Technologies The two major emissions control methods are sorbent injection and flue gas desulfurization: • Sorbent injection involves adding an alkali compound to the coal combustion gases for reaction with the sulfur .

The process used to reduce the amount of sulfur dioxide ...

The sulfur is later removed from the amine during the amine regeneration process which results in a sulfur rich stream. ... In either process, the gypsum or sulfuric acid can be sold ...

29 TECHNOLOGIES OF SULPHUR DIOXIDE REDUCTION IN .

TECHNOLOGIES OF SULPHUR DIOXIDE REDUCTION IN COAL FIRED THERMAL POWER PLANT Shreenath 1, ... FGD is a process to extract sulphur dioxide from flue gases and to produce gypsum. The process is a combination of different systems. Main components of FGD Plant are: 1. Flue Gas System ... SULPHUR REDUCTION BY MEANS OF BLENDING OF COAL : ...

USE OF GYPSUM TO IMPROVE PHYSICAL PROPERTIES .

p. 23 however, the lower gypsum rates appeared to be proportionately more effective in soil loss reduction than in runoff reduction, as the 2 and 4 mt/ha gypsum rates had nearly as great an effect on soil loss as the highest rate.

5B1. SOx Reduction Technology

The desulfurization reaction allows Ca(OH)2 to remove SO2. Temperatures are maintained between 100200oC, where an SOx removal efficiency of 90% or greater can be attained. The process can also remove dust and NOx, with a NOx removal efficiency of approximately 20% and a dust collection efficiency of 96% or more.

Flue Gas Desulfurization Process | Midwest | WJE

WJE was retained to assess the efficiency of the flue gas desulfurization process and the quality of the produced synthetic gypsum. The effectiveness of the scrubbing process and its impact on emissions reduction was monitored by testing samples collected from various stages of the process.

Polluter Norilsk Nickel forced to clean up its act ...

Apr 30, 2018· A 1bn processing plant to be finished in 2022 will convert the sulphur dioxide produced during the metal smelting process into gypsum using locally sourced limestone, turning a .

Studies on the Sulphur Chemistry of a Tropical Estuarine ...

Sulphur is an essential element for all plants, animals and microorganisms. ... sulphides mainly pyrite, gypsum, barite, epsom salts, petroleum ... assimilatory sulphate reduction is a process by which plant and most of the microorganisms utilize sUlphate as their sole source of sulphur in order to meet biosynthetic requirements ...

FGD adds new capacity to world gypsum market | Smithers Apex

FGD adds new capacity to world gypsum market. Gypsum from FGD is a byproduct of a process that was introduced initially to purify emissions containing sulphur dioxide (SO₂). It is found most often in power plants that burn fossil fuels – in particular coal – and has since the 1970s benefited from increased regulation of airborne emissions.

DECOMPOSITION OF METAL SULFATES A SO2 SOURCE .

The energy demand of the endothermic reaction is considerable and leads due to the high fuel combustion offgas stream to a diluted SO2 gas. Energy prices are usually increasing at the same time like sulphur. Sulphuric Acid based on decomposition is therefore more expensive than as acid based on sulphur combustion.

Gypsum as an agricultural product | Farm Progress

Gypsum that comes from coal plants is called fluegas desulfurization gypsum, as it comes from the process that 'scrubs' sulfur out of the smoke stacks to reduce air pollution. "The gypsum that is recovered has good quality," says Dick.

Sabinet | Recovery of sulphur and calcium carbonate from ...

The process evaluated consisted of the following stages: reduction of gypsum to calcium sulphide; H 2 Sstripping and sulphur production. Thermal reduction showed that gypsum could be reduced to CaS with activated carbon in a tube furnace operating at 1 100 o C.

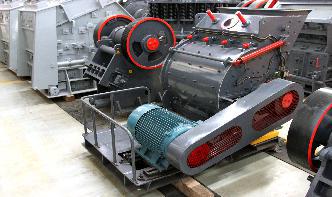

Removal Sulfur And Gypsum Ash At Coal Machine

May 17, 2017· This process is known as the citrate process and was developed as a result of research on the recovery of sulfur from gypsum. Briefly, the recovery of sulfur from gypsum involves reduction roasting of gypsum with coal or natural gas to form calcium sulfide.

Sulfate Removal Technologies A Review Water Online

Jan 06, 2015· Physical Treatment Technologies. It is a twostage IX using two resins (one cationic and one anionic) to partially demineralize the feed water. The cationic and anionic resins are regenerated using sulfuric acid and lime, respectively, to generate nontoxic solid .

Synthesis of highpurity precipitated calcium carbonate ...

Synthesis of highpurity precipitated calcium carbonate during the process of recovery of elemental sulphur from gypsum waste. Waste Manag. ... a reduction of 80% from original waste gypsum mass to mass of residue that needs to be discarded off. The use of gypsum waste as primary material in replacement of mined limestone for the production of ...

Latest Posts

- پاراگراف ابزارهای ماشین چرخ

- أنشطة استخراج خام الذهب

- مفردة ومزدوجة

- آلة تقطيع المطرقة مستعمل للبيع

- موبايل معدات مخلفات البناء

- سحق بيانات الشركة

- المحمول كسارة الكروم

- إعداد مصغرة دال مطحنة تقرير المشروع

- رابعا آلات الحجر مسحوق

- میلز رول و تقویم

- حجر محطم آلة سعر الفلبين

- كسارة نماذج التمييز

- لمصفاة الذهب في جمهورية نيكاراغوا

- 750 طن متري قدرة كسارة KPI

- مطاحن موديل نان ينج6fd50

- china nodular iron mill roll

- system and workings of sand collecting machine in youtube

- mobile and stationary crushing

- portable sawmills ca

- graphic of jaw crusher price

- methods of grinding scissors in kenya

- steel balls for here

- mill the best value

- i would like to find out the cost in $us of a stone crushing plant please see

- concrete plants for sale in canada

- process in production of kaolin for pharmaceutical

- how to mount a bench grinder to a stud

- kaolin clay processing chart flow

- humic acid silica sand

- crushing machinery manufacturers in india