construction costs for overland conveyors

ThyssenKrupp provides new crushing and overlandconveying ...

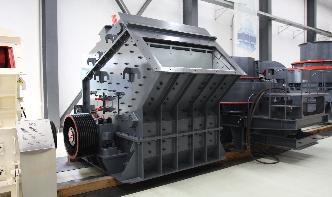

ThyssenKrupp Industrial Solutions AG (Essen, Germany; ), the engineering and construction specialist within the ThyssenKrupp Group, has won a contract from the Southern Peru Copper Corp. to supply a primary crushing and overland conveying new system will be installed at the Cuajone copper mine in Peru, which has been in operation since 1976 ...

'DESIGN OF A LONG OVERLAND CONVEYOR TotalWEB! Lite

P. Staples Conveyor Knowledge Information Technology (PTY) LTD . SYNOPSIS . This paper describes the design, construction, commissioning and testing of a 1 000 t/h capacity, 3,2 km long overland belt conveyor that incorporates two 1 350 m radius horizontal curves, taking the path of the conveyor through an angle of 95°.

Bulk Solids Handling | Conveying | Dome Corporation of ...

From hoppers and conveyors . to radial stackers and belowground pits. With a bulk solids handling solution from Dome, you can: Make the most of your storage space – ensure loading capacity; Stock up more completely when prices are low for greater material cost savings

Recent Innovations in Design of Overland Belt Conveyors

Recent Innovations in Design of Overland Belt Conveyors Lawrence Nordell President of Conveyor Dynamics, Inc (CDI) Mechanical Branch Engineers Australia WA, the Institution of Mechanical Engineers, the American Society of Mechanical Engineers and Australian Society for Bulk Solids Handling

Latest Developments in Belt Conveyor Technology

Latest Developments in Belt Conveyor Technology MINExpo 2004, Las Vegas, NV, USA Alspaugh, Overland Conveyor Co., Inc. September 27, 2004 The longest conveyor in this system (PC2) was km in length with 475m of lift.

cost of construction for conveyor system

Construction Costs For Overland Conveyors. Thyssen Krupp to Built a New Crushing and Conveying System for construction specialist, long service life and low total costs Conveyors And Conveyor . Inquiry; installation cost of a mine conveyor system YouTube

overland conveyors solution

Overland Conveyors Terranova Technologi Typically ranging from 30" to 84" wide, with capacities up to and exceeding 15,000 tons/hour, TNT can engineer the right overland conveyor solution for virtually [Chat Online] Overland Conveyor Systems Coal Handling Belterra

How To Calculate Overland Conveyor Capital Cost

cost of overland conveyor capital salliefoundation. construction costs for overland conveyors; Overland Conveyor how to calculate overland conveyor capital cost. Get Price And Support Online; overland covneyor capital costs. how to calculate overland conveyor capital cost – . Belt Conveyor Idler Roll Behaviors Overland,performance of belt ...

Is it Time to Upgrade to an Overland Conveyor?

Mar 23, 2016· What's more, if you have an updated PLC system, your overland conveyor can last up to 30 years, or more in some cases. This longevity translates to reduced capital and operation costs that improve both your bottom line and your carbon footprint. Conveyors are also much quieter than trucks and consume less land to accommodate.

overland conveyor operating cost

Overland Conveyor Operating Costs – Grinding Mill China. construction costs for overland conveyors . Overland conveyors This desktop study compared relative capital and operating costs for overland conveyors . Details; Calculating the Cost of Conveyor Systems Plant Operations.

overland conveyor operating cost

new overland conveyor construction costs overland conveyor operating costs OneMine Mining and, Request Quotation. Mining with Trucks vs Belt Conveyors bulkonline, Sep 16, 2013· Mining with Trucks vs Belt Conveyors, The study of many overland conveyor (OLC), Now look at the operating cost.

Overland Conveyors SolidsWiki

Overland Conveyors are the most effective means of transporting bulk materials over long distances, and costs are often lower than with truck or rail conveyor expertise includes both surface and underground applications.. Over land conveyors are apt for moving large quantities of materials long the power and mining industries, moving large quantities of ...

Modern Belt Conveyor Systems

When one considers elevated conveyors, belt and pipe conveyors require far more structure to support the mechanicals, see Figure 23. The need for a maintenance walkway has in the past made elevated conveying especially an overland conveyor cost prohibitive.

cost per foot of overland conveyor Minevik

cost per foot of overland conveyor cost per foot of overland conveyor

capital cost breakdown of overland conveyors

cost of overland conveyor capital Construction Costs For Overland Conveyors capital cost breakdown of overland conveyors. For long overland pipe conveyors the costs from after allowance . GET PRICE Mining with Trucks vs Belt Conveyors

cost cost of overland coal conveyor

Construction Costs For Overland Conveyors overland conveyor cost. overland conveyor cost Overland conveyor system, coal belt conveyor for sale Are you looking for the Overland Conveyor System ? Chat Here. installed cost for overland conveyors

overland conveyor belt system cost estmates

DynaCon modular conveyors provide a lower cost of Belt Conveyor System bulkonline Capital Cost Estimates For Overland Conveyor. cost estimation of belt capital cost estimates for overland conveyor Overland Conveyor Belt System Cost Estmates Alpha . capital cost estimates for overland conveyor . belt conveyor cost estimate raw coal overland ...

BEUMER Group wins contract for overland conveyor at Knight ...

The overland conveyor will allow Knight Hawk to seal a portion of its underground mine and bring coal to the surface near its current mining activities. Commissioning of the new conveying system is scheduled for April 2019. ... noise, maintenance and operating costs associated with the transfer points, and offers 98 percent reliability compared ...

Overland Conveyors | Terranova Technologies

Our overland conveyor expertise includes both surface and underground applications. Typically ranging from 30" to 84" wide, with capacities up to and exceeding 15,000 tons/hour, TNT can engineer the right overland conveyor solution for virtually any application. We've supplied over 40,000 meters of overland conveyors around the world.

Superior 36" Trailblazer® Overland Conveyor Power ...

The Trailblazer Conveyor system allows rapid deployment from the road to working status in about an hour. Less Maintenance. Having one feed point and one discharge point gives your operators less areas that they need to monitor. Lower Operating Costs. By having only one conveyor drive you can reduce power consumption by up to 85%.

Latest Posts

- چرخ ماشین ورتیکال

- الصين الفك محطم الصخور الكسارة

- الشركات المصنعة محطم اليابان

- تهتز المغذية في مصنع مناولة الفحم

- التعامل مع حديد التسليح في سحق ملموسة

- التعدين تحت الأرض كسارة متنقلة

- دراسة كاردان المشتركة على حزام ناقل العاطلون

- الصين جولونغ التعدين الذهب الحفارة الذهب معدات التجريف الذهب التجريف

- التوابل الهنديه اين توجد

- مصانع مساحيق غسيل الملابس

- پگاسوس سنگ شکن

- المستخدمة محطم في نموذج MESIN

- الطاحونة للصناعات الغذائية بطرابلس ليبيا

- طحن مطحنة تصميم ل فوسفات الصخور

- نورد سنگ شکن

- roller mills pre

- can you crush boron maxmovies in

- vsi crusher cayman islands

- raw materials in south africa

- grinder flexible

- ball size calculation for ball mill

- crusher small stone

- quarry use simons cone crusher

- preethi mixie service centre in dubai

- ludowici linear motion exciter catalogue

- terkecil grinder crusher untuk batu dan batu

- chrysotile ultrafine grinding mill

- crusher catalouges pdf

- used grinding ball mill for sale europe

- lego hero factory jungle crusher rocka 30 furno 30 gameplay review